a plumber cant fit a solid fuel boiler, hetas registration is requiered similar to part p, a solid fuel appliance should be registrered to local building control.

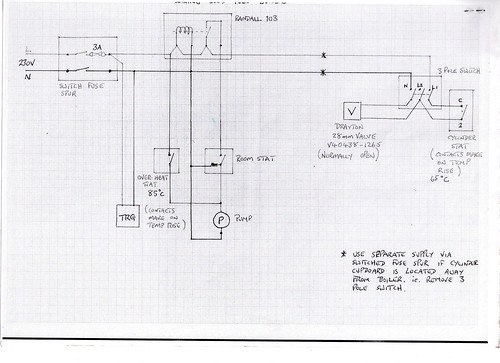

to conform to current building regs stored water under part L of the conservation of energy states that water should be stored no hoter than 60 degrees. therefore a form of thermostat is req to comply. we fit normally open 2 port zone valves which is different to the powered open you would see on a normal heating. (if power shuts off it would boil up so its for safety.)

to take the excess heat away when the gravity sercs are closed to the cylinder this is when the heat leak is req usually a 1200 x 600 dc radiator on the gravity sercs .. a final safety is the high limit stat on the flow pipework that brings the pump on at over 89 degrees.

this is the way to pipe and wire a a solid fuel boiler i fit solid fuel regualrly for a local council and this is how hetas req the instalation to be completed and i have been inspected many times over the years so am 100% correct.

its a actually a speciallity of mine .

in the old days we fitted injector tees to seperate the return flow of the heating and hot water to make the gravity return a priority.

there is nothing wrong with piping up a solid fuel boiler without any of the controls just gravity hot water and pumped heating and will work perfectly well but if you want it to comply all the above is req.

remember you need a certifiate of compliance as if anything happens it may invalidate your house insurance.

i will uplaod a diagram for you to the uploads section as we speak .