- Joined

- Dec 25, 2011

- Messages

- 5,456

- Reaction score

- 69

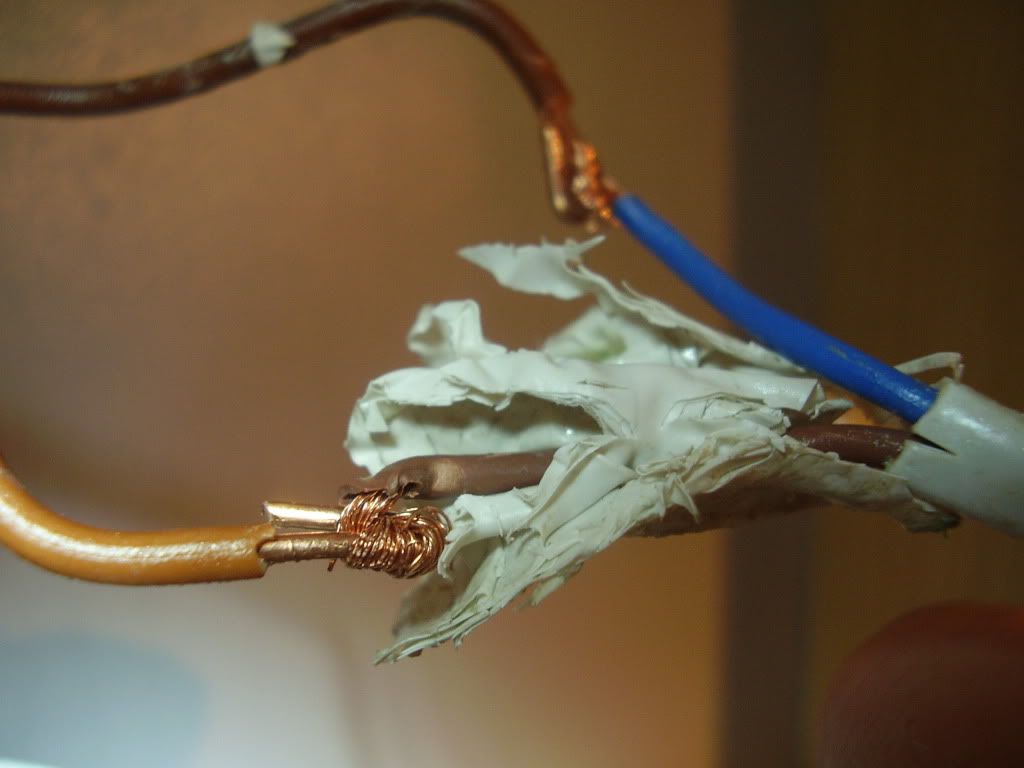

Going to sound daft but here goes...............electric igniter on a GAS hob...................how are these usually wired? (I hate anything gas tbh and grew up where there wasn't any). I've posted this pic before (one of many "to sort" jobs on a buy to let. Previously both the single leccy oven and gas hob were wired like this:

Nice eh? Looks like someone's 110 lead's a bit short! How that 1G socket was fed is a whole other story. Anyway, all gone now. Oven will be off 20A neon DP switch above worktop and un-switched 1G socket below. But the supply for the igniter........I COULD just plug it in to a socket accessible through the back of a cupboard. Just wondered what was usual. Seems a bit overkill to have it on a switch above the worktop. As I said not come across a gas igniter before! Thanks in advance.

Nice eh? Looks like someone's 110 lead's a bit short! How that 1G socket was fed is a whole other story. Anyway, all gone now. Oven will be off 20A neon DP switch above worktop and un-switched 1G socket below. But the supply for the igniter........I COULD just plug it in to a socket accessible through the back of a cupboard. Just wondered what was usual. Seems a bit overkill to have it on a switch above the worktop. As I said not come across a gas igniter before! Thanks in advance.