You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Belling out

- Thread starter L-E_Fault

- Start date

Help Support Talk Electrician Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Status

- Not open for further replies.

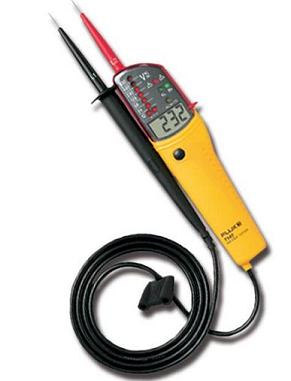

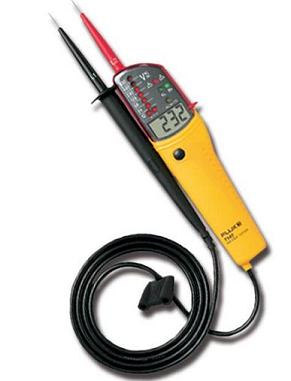

Fluke T140 (well, thats what i use. there are more basic models available - i.e T100)

stick leads between point you want to test... or if its not long enough, make use of an extra core in the cable, or a roll of 1.5mm singles comes in useful

- Joined

- Jun 21, 2008

- Messages

- 16,999

- Reaction score

- 27

we just talking about basic continuity here?

yes

green-hornet

Distinguished Member

- Joined

- Feb 25, 2009

- Messages

- 3,741

- Reaction score

- 0

Belling out is an old term where continuity was checked by use of a bell or buzzer and a battery, some where little lights.

The small current from the battery was sent down the cable being checked which completed the circuit and sounded the bell or buzzer.

The small current from the battery was sent down the cable being checked which completed the circuit and sounded the bell or buzzer.

The term " Belling out" comes from using a what we called a "bell set" which was what it sounds, a doorbell taped to a battery with two leads and croc clips.

If you have 20 unmarked cables pick one as common for one side of the bell (or use earth) then touch the others down one at a time and number them .

I still use one , one of the best ways of identifying cables, you can hear it ringing from upstairs ,say .

I thought every one had one !!

If you have 20 unmarked cables pick one as common for one side of the bell (or use earth) then touch the others down one at a time and number them .

I still use one , one of the best ways of identifying cables, you can hear it ringing from upstairs ,say .

I thought every one had one !!

Blimey I've been there, it hadn't been open long, is it near Newcastle ?nah - gave mine to beamish many years ago

It was full of old bell sets. :coat

its between chester le st and stanley. bout 10 mile south of newcastle

Yes remember going there when we were working in Newcastle (British Lead Co. if memory serves) .

did you use any old VIR cables and fused neutrals when working there?! (keep everything to date!)

Not stupid at all , you'll never know if you don't ask, we're all learning all the time, except Specs , of course who knows absolutely everythingI've heard people talk about belling out and know its what you do to identify cables. But what tools do you use? Sorry if this is a basic/stupid question?

Tim

There are more questions than answers and the darkest hour is just before dawn. I'm losing now, think I need my medication.

No I bloody didn't !! They were cotton braided. We used to convert those huge overhead cranes to radio control. Remove the cab controls so the driver had to work on the shop floor until they wanted the crane. Two weeks building the panel at the workshop then one week on site , 12 hour days and a lot of travelling but interesting work. Crane motors were all slip-ring with old fashioned drum controllers which had to be replaced by the controls in our panel.did you use any old VIR cables and fused neutrals when working there?! (keep everything to date!)

Long time ago now , not only has the water stopped running under the bridge, the bridge is no longer there.

sounds like an interesting jobNo I bloody didn't !! They were cotton braided. We used to convert those huge overhead cranes to radio control. Remove the cab controls so the driver had to work on the shop floor until they wanted the crane. Two weeks building the panel at the workshop then one week on site , 12 hour days and a lot of travelling but interesting work. Crane motors were all slip-ring with old fashioned drum controllers which had to be replaced by the controls in our panel. Long time ago now , not only has the water stopped running under the bridge, the bridge is no longer there.

ian932

Senior Member

Last edited by a moderator:

green-hornet

Distinguished Member

- Joined

- Feb 25, 2009

- Messages

- 3,741

- Reaction score

- 0

We have used a similar phone with a cable called D10, used by the military for field communications.

Great for finding the ends of lost or chopped cables

Great for finding the ends of lost or chopped cables

- Status

- Not open for further replies.

Similar threads

- Replies

- 20

- Views

- 1K

- Replies

- 13

- Views

- 509