If you had to test a whole installation that someone else have done, do you have a checklist of elements you shall be doing to see if everything is in the right place?

I'm like to write it down. Some elements I've been thinking on, I would like if you could write 1 or 2 I've missed, I will be updating the list to have a good and comprehensive list with all the best items that should be tested.

I just want to have a checklist for personal uses. If you think any other interesting or important test should be done, please comment.

I'm like to write it down. Some elements I've been thinking on, I would like if you could write 1 or 2 I've missed, I will be updating the list to have a good and comprehensive list with all the best items that should be tested.

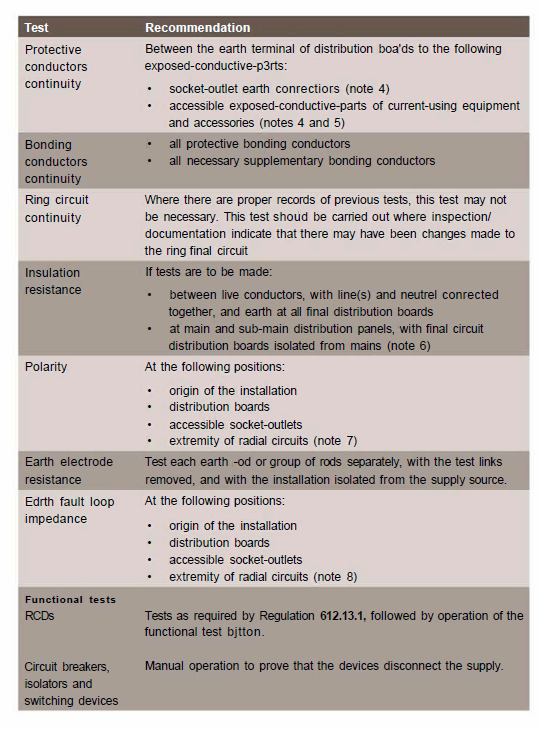

- Continuity of protective and ponding conductors

- Continuity of ring final circuit

- Insulation resistance with a meg tester

- Polarity testing

- Earth electrode resistance

- Earth fault loop impedance

- RCD disconnection timing

- Phase rotation/sequence test

- Functional testing

- Voltage drop

- Thermal analysis with thermal camera

- Harmonic distortion with network tester

I just want to have a checklist for personal uses. If you think any other interesting or important test should be done, please comment.

Last edited: