Hi all,

Before I start I'm guessing this has been talked about over and over again and I have read several threads about this, some quite old, so apologys but wanted to get a more updated view.

I would like to know the best (safest and i guess meets regs) method to move sockets where extending the cable is the only option and being able to bury the connection in the plaster board / wall and plaster over, never to be accessed again.... hopefully!

I have read all about WAGO connectors in WAGO box, are these classed as MF yet? and how do you bury such a big box in plaster?

I have also seen the LINE products with the LINE enclosures which look smaller to bury in plaster board and are MF are these best to use?

I have also seen the Ashly JB MF boxes, I guess these are not as deep as the WAGO box at 30mm and can be buried in the wall and then plastered over bit easier?

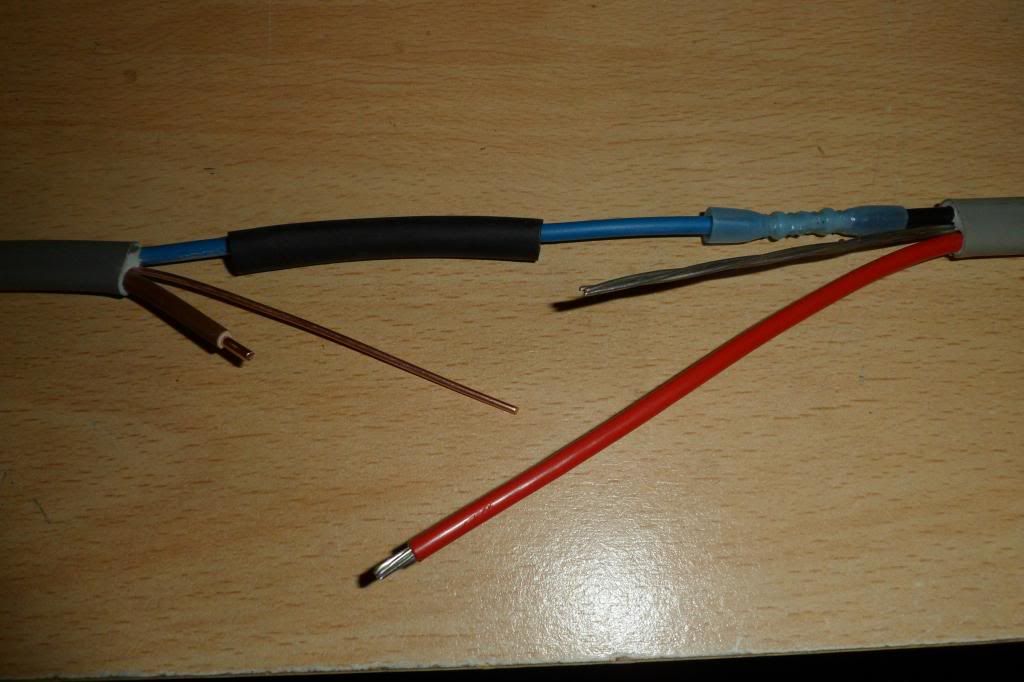

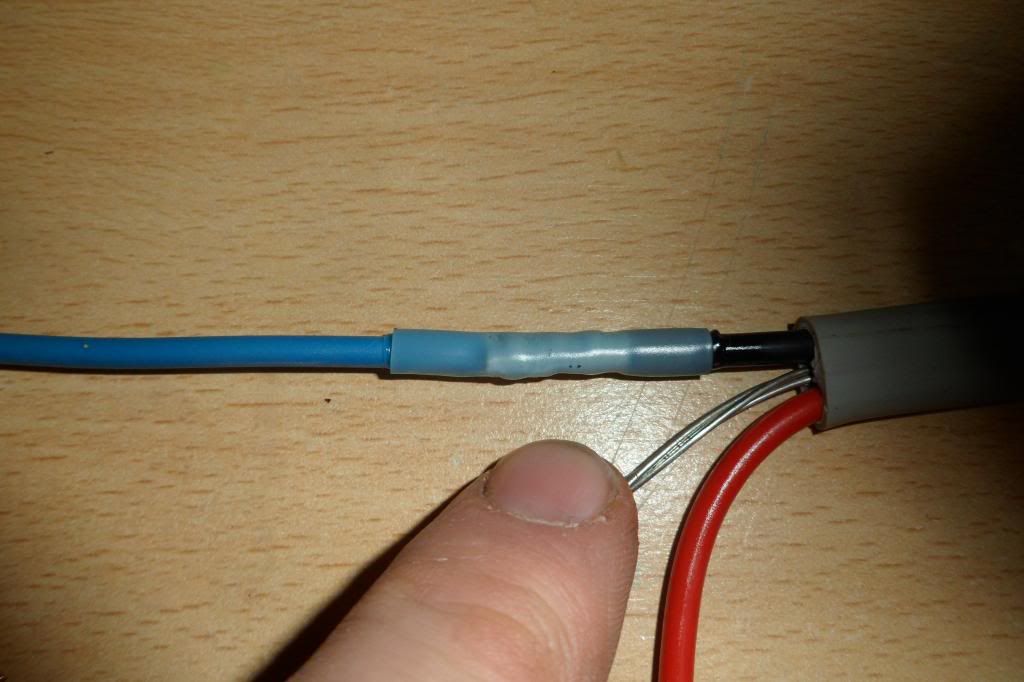

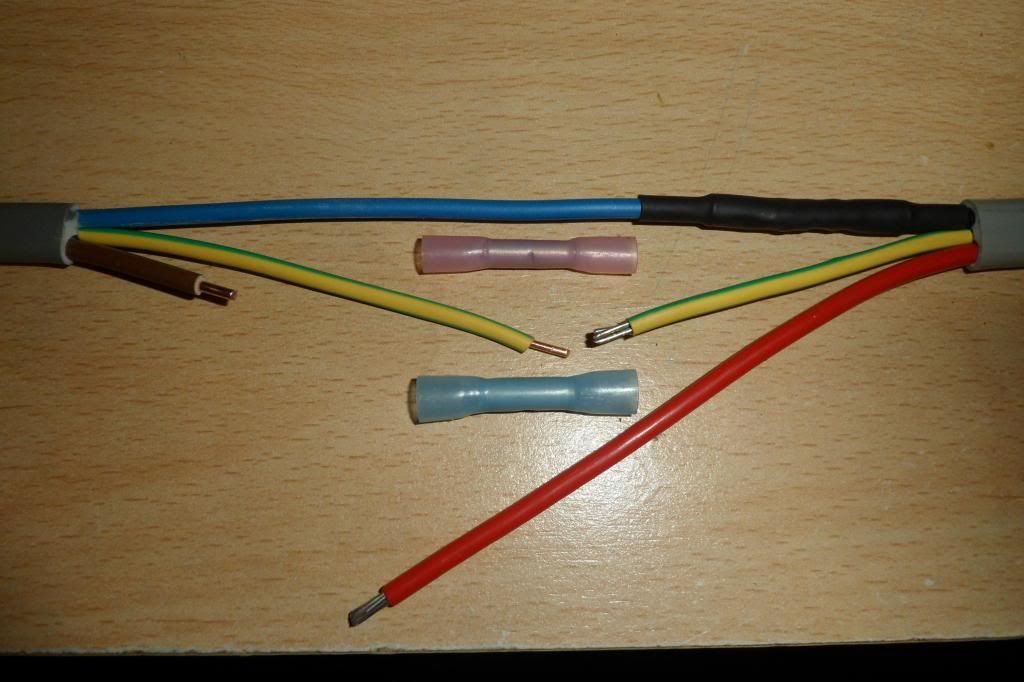

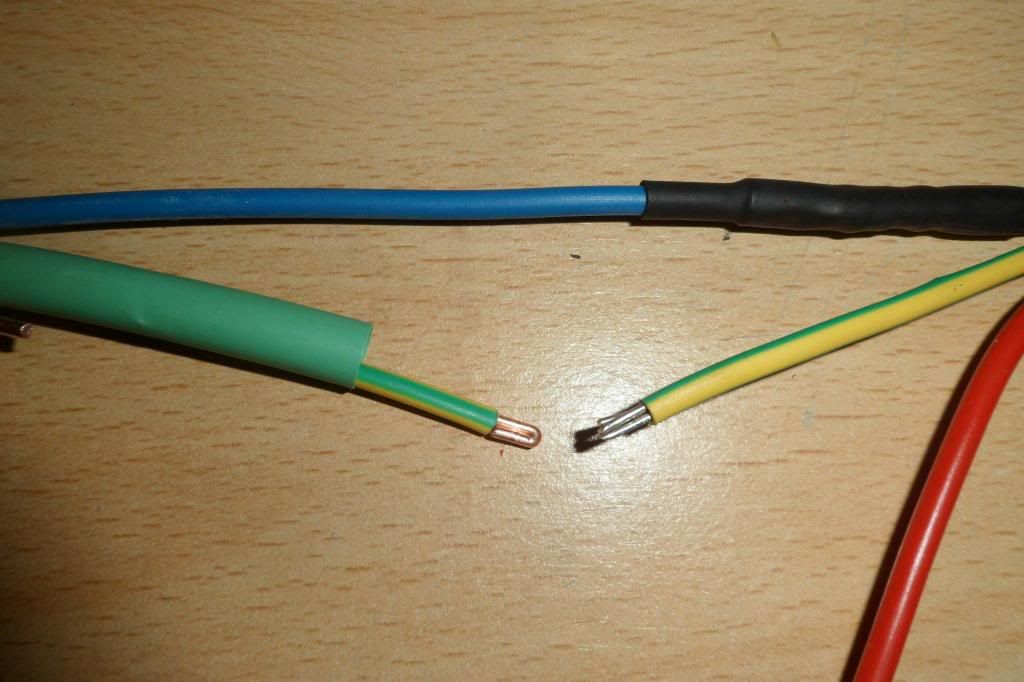

Or is simply crimping using a Racheting Crimper the best method, and would these need to be in a box in the wall or can you simply crimp, heat shrink and place into the chased out section of the plaster board and plaster straight over the top? - but should you crimp solid core copper? I have heard both yes and "you would be stupid to"

cheers guys

Before I start I'm guessing this has been talked about over and over again and I have read several threads about this, some quite old, so apologys but wanted to get a more updated view.

I would like to know the best (safest and i guess meets regs) method to move sockets where extending the cable is the only option and being able to bury the connection in the plaster board / wall and plaster over, never to be accessed again.... hopefully!

I have read all about WAGO connectors in WAGO box, are these classed as MF yet? and how do you bury such a big box in plaster?

I have also seen the LINE products with the LINE enclosures which look smaller to bury in plaster board and are MF are these best to use?

I have also seen the Ashly JB MF boxes, I guess these are not as deep as the WAGO box at 30mm and can be buried in the wall and then plastered over bit easier?

Or is simply crimping using a Racheting Crimper the best method, and would these need to be in a box in the wall or can you simply crimp, heat shrink and place into the chased out section of the plaster board and plaster straight over the top? - but should you crimp solid core copper? I have heard both yes and "you would be stupid to"

cheers guys